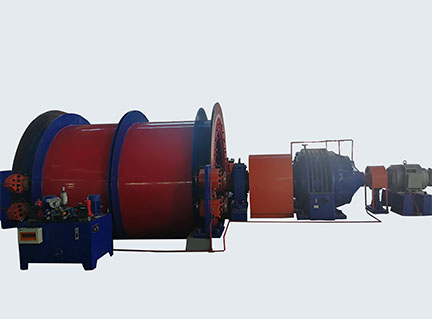

The product is composed of power system, transmission system, working system, braking system, control operating system, indicating protection system and its accessory parts . It uses the electric motor power source, through the reducer, the spindle device constitutes the product efficient transmission system and the working system .The hydraulic station and brake device constitute the reliable brake system of the product. A complete product control operating system is composed of operating table and electrical control equipment. It is composed of depth indicator, encoder device etc.

| 2JK Model Double Drum Electric Mine Hoist System | ||||||||||||||||||||

| No. | Model | Drum | Max static tension of wire rope | Max static tension difference of wire rope |

Max lifting height or Length of transportation |

Wire rope |

Reduction ratio |

Average lifting speed |

Motor |

Dimensions L*W*H |

Thoretical weight |

|||||||||

| Qty | Diameter | Width | Two drums central distance | Manned | Load | Manned | Load | 1 layer | 2 layers | 3 layers | Max Dia |

Aggregate breaking pull force |

Rotating speed |

Max power | ||||||

| Unit | mm | KN | m | mm | KN | m/s | r/min | KW | mm | kg | ||||||||||

| 1 | 2JK-3.5*2.1P | 2 | 3500 | 2100 | 2190 | 170 | 115 | 494 | 994 | / | 43 | 1230 | 30 | 4.6 | 750 | 630 | 12150*5020*4060 | 97011.7 | ||

| 2 | 2JK-3.5*1.7P | 2 | 3500 | 1700 | 1790 | 136 | 170 | 115 | 424 | 853 | 1283 | 43 | 1230 | 30 | 4.6 | 740 | 630 | 10360*5020*4060 | 87031.7 | |

| 3 | 2JK-3*2P | 2 | 3000 | 2000 | 1890 | 130 | 80 | 483 | 972 | 1467 | 36 | 900 | 30 | 3.9 | 740 | 630 | 13560*4680*2730 | 71687.7 | ||

| 4 | 2JK-3*1.5P | 2 | 3000 | 1500 | 1590 | 100 | 135 | 90 | 371 | 747 | 1126 | 36 | 900 | 30 | 3.9 | 741 | 400 | 10060*4380*2730 | 68687.7 | |

| 5 | 2JK-2.5*1.5 | 2 | 2500 | 1500 | 1590 | 69 | 83 | 65 | 369 | 742 | 1119 | 30 | 621 | 31.5 | 4 | 974 | 245 | 8520*3610*2600 | 44354 | |

| 6 | 2JK-2.5*1.5P | 2 | 2500 | 1500 | 1590 | 69 | 83 | 65 | 369 | 742 | 1119 | 30 | 621 | 31.5 | 4 | 974 | 260 | 8520*3610*2600 | 44354 | |

| 7 | 2JK-2.5*1.2P | 2 | 2500 | 1200 | 1290 | 69 | 83 | 55 | 294 | 591 | 892 | 30 | 621 | 31.5 | 3.1 | 740 | 250 | 7374*3610*2600 | 39989 | |

| 8 | 2JK-2*1.25 | 2 | 2000 | 1250 | 1340 | 44 | 61 | 40 | 296 | 595 | 898 | 24 | 396.5 | 31.5 | 4 | 973 | 132 | 7960*3234*2600 | 27798.5 | |

| 9 | 2JK-2*1.25P | 2 | 2000 | 1250 | 1340 | 44 | 61 | 40 | 296 | 595 | 898 | 24 | 396.5 | 31.5 | 4 | 973 | 132 | 7960*3234*2600 | 27798.5 | |

| 10 | 2JK-2*1P | 2 | 2000 | 2100 | 1090 | 44 | 61 | 40 | 236 | 475 | 717 | 24 | 396.5 | 31.5 | 3.1 | 740 | 160 | 6740*3234*2600 | 25937 | |

| A.The minimum safety coefficient of the wire rope conforms to the following provisions: 1.Specially for lifting people 9 times .2. Lifting personnel and materials (9 times when lifting personnel, 7.5 times when lifting materials);3, Specially for lifting materials 6.5 times. | ||||||||||||||||||||

| B.The ratio of the diameter of the winch drum to the diameter of the wire rope shall not be less than 80 times;The ratio of drum diameter of downhole winch shall not be less than 60 times. | ||||||||||||||||||||

| C.The number of layers of wire rope winding on the drum shall comply with the following provisions: 1. One layer of lifting personnel and materials in the vertical shaft , two layers specially for lifting material . 2. Two layers of lifting personnel and materials in the inclined shaft , three layers specially for lifting materials .3. Two layers of lifting personnel and materials during the shaft construction . | ||||||||||||||||||||

The single rope mine hoist system is mainly used for vertical shaft , inclined shaft to lift people , materials and equipments in coal mines , metallic mines and non-metallic mines . It can also be used for traction transportation .

a.The working conditions of the single drum mine hoist system The mine hoist system shall be installed in the machine room with air temperature 0°C-40°C, relative humidity not more than 85% (ambient temperature 20°C±5°C) , the altitude not more than 1000m . It shall be able to prevent liquid from immersing into the internal of the electric appliance and work in the environment without violent vibration , jolt or corrosive gas . When the altitude exceeds 1000m , the cooling effect of air and the decrease of dielectric strength shall be considered . The selected electrical equipment shall be designed or used according to the agreement between the fabricator and user .

b.The layer of drums on the mine hoist system :

(1)1 Layer used to lift people or lift people and materials in vertical shaft ; 2 layer is used to lift materials.

(2)2 layers is used to lift people and materials in inclined shaft , 3 layers is used to lift material .

(3)The connection point which the rope transfers from the lower to the upper (equivalent to a quarter of the loop ) must be checked frequently and the rope should be moved quarter of the loop every three months .

Note:

(1) JK model mine hoist system is strictly prohibited for gas, coal dust and other inflammable , explosive gas places ! JKB can be used in above conditions.

(2) The mine hoist system is strictly prohibited from overload operation !

(3) Overspeed and power failure are strictly prohibited !

We respond immediately to any questions , inquiries and needs , feel free to contact us at any time .