1.What is overhead crane

Overhead crane is kind of equipment that is used for lifting and conveying materials across the workshops , warehoused and stock ground . Its ends locate on the tall cement column or metal column , when it is installed in workshop , it looks like bridge .The bridge frame can travel lengthways along the track laid on both sides of columns , the electric hoist will travel crosswise along the main girder of overhead crane , it can make full use of space below the overhead crane to lift or transfer the materials unencumbered by the ground equipments .For the firms to save cost and improve the work efficiency , increase the output value is a good choice .

2.How to choose crane for lifting ?

In order to picking the suitable crane , these key elements should be considered .

2.1 Environment

This is the precondition for choosing the overhead crane , before choosing the overhead crane , the two simple questions need to be definited , what occasion will the crane be used ? what materials will be lifted ? The overhead crane is suitable for the most general purpose , but there are some other special use environments , for example , the environment is with low temperature , heavy dust , corrosive or explosive etc

2.2 The rated capacity

Picking the right capacity is very important to extend the life span of the crane , for example , the weight is 10 ton , if the crane usually lift the material with full capacity , we suggest the 15 ton , 10 ton is good choice as well , it will accelerate the broken of wearing parts and tear of the bridge structure . If the crane usually lift with 5 ton material but less times to lift 10 ton , so this is better to pick 10 ton .

2.3 The lifting height

This is also the important element that to be considered , it will determined whether the material can be lifted at required height . If the general crane can’t reach the lifting height because of the structure of workshop , we can suggest the low headroom hoist and change the bridge structure to meet the requirements .

2.4 The speed of overhead crane

This factor is also ignored by the clients , Typically the standard speed can meet most general purpose , but you need to consider whether it is suitable for you or not .The lifting speed and travelling speed need to be clarified before sending the quotation .

2.5 The control methods

Now it has three control methods , pendant cable , remote control and cab control , picking the suitable one .

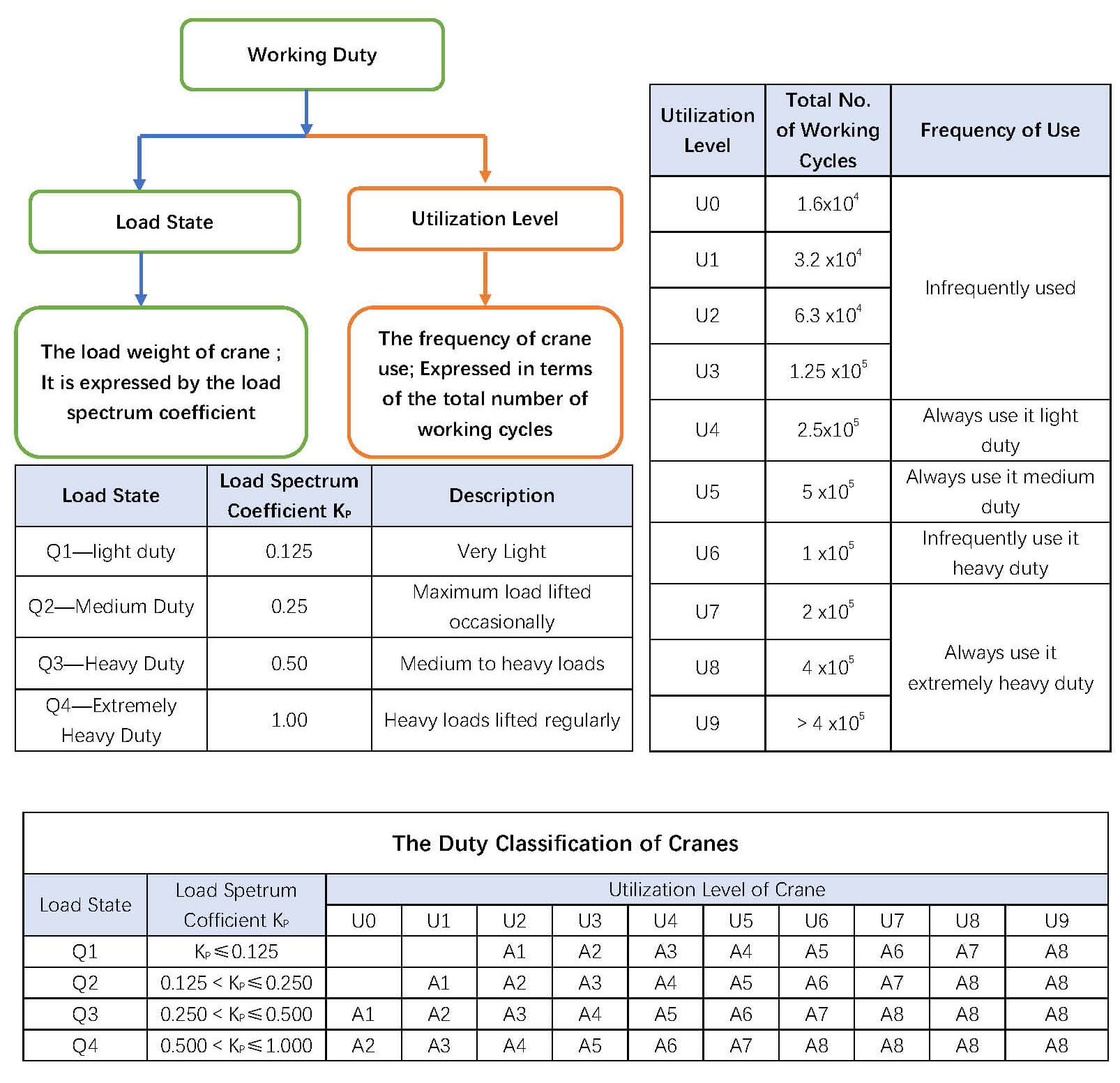

2.6 The overhead crane duty classification

It is very important factor to pick the overhead crane , this will be showed the 3 with table .

3.Overhead crane duty classification

It is the main technical parameter of overhead crane , frankly speaking it’s the duty classification of steel structure , classified by the lifting mechanism , it can be A1-A8, equivalent : A1~A4---Light duty , A5~A6---Medium duty , A7---Heavy duty , A8 Extremely heave duty . The duty classification is determined by the crane’s utilization level (the total number of working cycles in the whole design life cycle ) and load state , which reflects crane’s working characteristics in load state and utilization of busy degree.

Different countries have different standards about the overhead crane duty classification , The following standard are often chose by the clients , for example FEA , CMAA , GB etc . Although the standards are different , they have the same load spectrum . Below GB standard table can be for reference .

The following table is for reference .

|

Crane Types |

Working Duty |

||

|

Overhead

Crane |

Hook Type |

Power Plant Installation and Maintenance |

A1 , A2 , A3 |

|

Workshop or Warehouse |

A3 , A4 ,A5 |

||

|

Heavy Duty Workshop or Warehouse |

A6 , A7 |

||

|

Grab Bucket |

Intermittent Loading and Unloading |

A6 , A7 |

|

|

Continuous Loading and Unloading |

A8 |

||

|

Used for

Metallurgy |

Lifting Metallurgical Bin |

A7 , A8 |

|

|

For Metallurgical Charging |

A8 |

||

|

For Foundry |

A6 , A7 , A8 |

||

|

For Forging |

A7 , A8 |

||

|

Gantry Crane |

Hook Type for General Purpose |

A3 , A5 , A6 |

|

|

Loading and Unloading Grab Bucket Type |

A7 , A8 |

||

|

Hook Type for Power Station |

A2 , A3 |

||

|

Hook Type for Shipbuilding Installation |

A4 , A5 |

||

|

Container Loading and Unloading |

A6 , A7, A8 |

||